During all of the manned Apollo moon missions just one engine was classed as so critical even the most insignificant or minor alterations had to be signed off by the very highest management in NASA.

That engine was the lunar ascent engine that lifted the ascent module from the lunar surface to orbit and rendezvous back with the command service module. This was considered the most critical part of the entire operation because if that engine didn’t start or failed in some way then there was no way to rescue the crew.

And yet with so much weight of responsibility on it, it was the only engine that was not lice fired as a complete unit prior to being fitted to the lunar Lander.

So how did something so critical have no test run prior to installation, something which was done to virtually every single component used in the Saturn rocket and lunar Lander.

Well to find that out we have to spool back a bit, to the design of the lunar Lander and the unique challenges that faced NASA and its contractors who built the Lander and the engines.

When John F Kennedy announced the manned moon missions in 1962, the US had about 15 mins of experience in orbit, let alone going to the moon and no one quite knew how they were going to land a man on the moon and get them back again.

Many including Apollo leader Werner von Braun suggested landing one large rocket but one man, NASA engineer John Houbolt suggested it would be far too large and carry far too much unnecessary weight.

His idea would be to split the large rocket into two where the command service module would remain in orbit while a smaller, lighter Lander would descend to the surface and return to rendezvous with the orbiting spacecraft before returning back to earth.

Few people thought Houbolt’s idea was serious and he felt he couldn’t compete against von Braun even though he thought his was the only way that it would work. In the end, he wrote to Robert Seamans, NASA associate administrator, to get a fair hearing.

After the meeting in which both the single rocket approach of von Braun’s team and Houbolt’s lunar orbit rendezvous Method were openly discussed, von Braun surprised everyone and chose Houbolt’s idea over his own and was now convinced that it was the only way to land on and return from the moon.

The contract to build the lunar Lander was issued to several aircraft companies but it was won by Grumman Aircraft, the company that had built many planes for both The US Navy and Air Force and was the last major contractor to join the Apollo program.

Grumman had being working independently on a lunar Lander for some time and as such showed the best ideas to get the job done. Their lander advanced Houbolt’s idea of a single Lander and created two stage craft that would descend and land on the moon, and then a smaller lighter ascent section would take off and leave the bulky decent section behind.

Some people thought that they were a bit out of their depth in creating a vehicle which had never existed before, to go to a place we had never been before and would only be tested to its fullest extent when it was actually performing the landing and take off from the lunar surface.

But Grumman used their aircraft experience to build what they thought would be the best way to get the job done.

While Grumman was building the Lander, they would subcontract the descent engine to TRW and the ascent engine to Bell Aerosystems.

This two-part lander came about because of the need to save weight, The whole Saturn 5 was a bit like a set of Russian dolls, with the biggest heaviest parts being discarded after they had been used, the remaining sections getting smaller and lighter and needing less fuel, with just the tiny command module returning the crew to earth with a parachute into the Pacific ocean.

And nowhere was this more critical than during the decent to the moon and the ascent from the surface back to orbit, the less weight that could be carried back the smaller the engine would need be and the amount of fuel required to do the job.

And this is where the other issues crop up. The main Saturn 5 rocket engine’s used kerosene and liquid oxygen as fuel and required several stages of ignition to get the F-1 engine’s working but the engine’s on the Lander needed to be small and to ignite in the vacuum of space and be 100% reliable.

The decent engine would need to be throttleable to control the thrust as the Lander descended from 50,000 feet to the surface, something which had not been done before, all previous rocket engines worked like an on-off switch with either full power or nothing.

The descent engine would also work as a backup in case of the failure of the Command service module engine, which is what happened to Apollo 13 after the explosion of an oxygen tank.

The ascent engine didn’t need to be throttleable but it would need to be as light as possible and again 100% reliable, if the descent engine failed during the landing, the crew would abort and the ascent engine would be their only source of thrust, if it failed to ignite or had a problem then the crew would be lost on the moon.

The most reliable way to start a rocket engine in space at the time at the time was to use hypergolic fuels.

These use fuel and oxidizer which combust on contact with each other, no other ignition source is required and they will work every time, even in the vacuum of space, ideal if you want to guarantee the engine starting.

The problem is that they are not only highly corrosive but also highly dangerous to humans and almost every other living thing, you’ve only got to see the warnings on the side of the containers of the Aerozine 50 fuel, a 50:50 mix by weight of hydrazine and unsymmetrical dimethylhydrazine and oxidizer Dinitrogen tetroxide, these were also used in the Titan II ICBM rocket engines in the late 1950s.

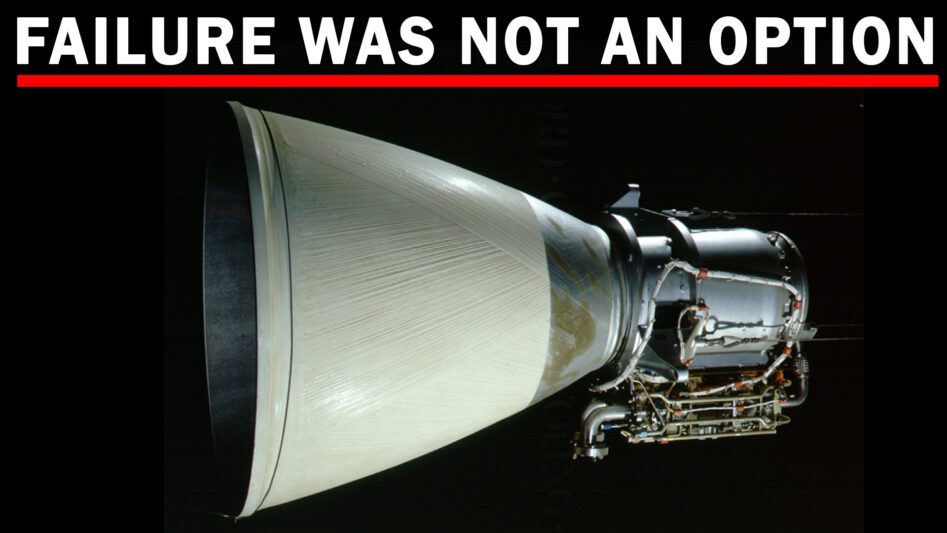

But the design of the ascent engine was actually incredibly simple, there were literally just a couple of valves which opened to allow the fuel into the combustion chamber, and a helium pressurised fuel system did away with the need for any pumps or turbines.

Although the engine was very simple because of the fuel used everything had to be just right, minor changes and modifications made a very big difference to the performance of the engine and one of the main problems that showed itself was combustion chamber instability, not unlike the issues that the Rocketdyne F-1 engine’s had.

In the mid 1960s, Bell Aerosystems developed the ascent ancient but had continuing issues with instability which could lead to the engine failing. Despite numerous changes of the injector plate to make it more stable they just couldn’t get it to work correctly or it created issues with other parts of the engine such as the erosion of ablative coating on the nozzle.

The weight of the ascent module was also growing due to extra demands which meant that the ascent engine had to either output more power or burn for longer, both of which we’re causing issues.

During testing it was found that the fuel and oxidizer were so corrosive that the engines had to be completely rebuilt after each test, this meant that for the engines of the lunar Lander, they could not be live-fired before they were fitted.

All they could do was to test run them to make sure the design worked and then build them as best as they could and then hope that everything else worked as expected.

Testing could only be done at the white sands test ground because of its remote location. If any spills of the fuel occurred, the red-coloured fuel vapour could be seen and if the wind was blowing in the direction of the base it would have to be evacuated immediately.

The fuel was so toxic that even five parts per million was considered to be very hazardous and could cause serious damage to lung tissue, eyes or the skin as well as its carcinogenic nature.

As we’ve said before the design was actually very simple, there was very little to go wrong providing everything was built as specified and components tested before the engine assembly.

The fuel and oxidizer were held in separate tanks and only when ignition was required would high-pressure helium be forced into the tanks causing the oxidizer and fuel to flow into the engine, this would happen just before the fuel valves in the engine would open to allow fuel and oxidizer to mix in the combustion chamber and ignite.

Although things were going OK, issues with the injector plate made by Bell forced Grumman to bring Rocketdyne in to create their own version of the injector plate as a backup, in case Bell couldn’t fix the issues and time was running out if they were to launch on time.

By May 1968, continuing tests had shown that the Rocketdyne inject plate was more suitable, so the engine would be built by Bell using a Rocketdyne injector under the direction of Grumman but by September 68, NASA directed Rocketdyne to assemble the ascent engine with the Rocketdyne injector plate leaving Bell to supply the parts.

Only testing in a real space environment would prove if all the work they had done had been worth it and on Apollo 9 and 10 both the decent and ascent engine’s performed as expected with no unforeseen issues, leaving the way open for the Apollo 11 mission to put the first men on the moon on July 20th 1969.

With exceptional attention to detail and with the saying “failure is not an option” above them Grumman, Bell and Rocketdyne succeeded in creating 100% reliability in the most hostile environment humans have visited.

It will be interesting to see if their successors can do the same in adapting more conventional methane LOX engine’s for the new moon race that is underway, now that hypergolic fuels have been removed from the missions.

So thanks for watching and I hope you enjoyed the video, and a big thanks goes to our patrons for their ongoing support.